Have you ever wondered what’s really happening when your 3D printer whirs into action? As incredible as it is to watch your projects take shape layer by layer, there might be more lurking in the air than you realize. Let’s chat about some lesser-known facts about 3D printing and why it might be time to start paying closer attention.

Do You Notice the Smell?

When you print with materials like ABS, you may notice a distinctive smell – that sticky, sweet, plasticky odor. Common sense might suggest it’s not ideal to inhale this regularly. Many people switch to ASA, thinking it emits fewer smells, but research suggests ASA can emit more harmful particles and volatile organic compounds (VOCs) than ABS. This serves as a crucial reminder: just because our noses don’t pick up on something doesn’t mean it’s not there.

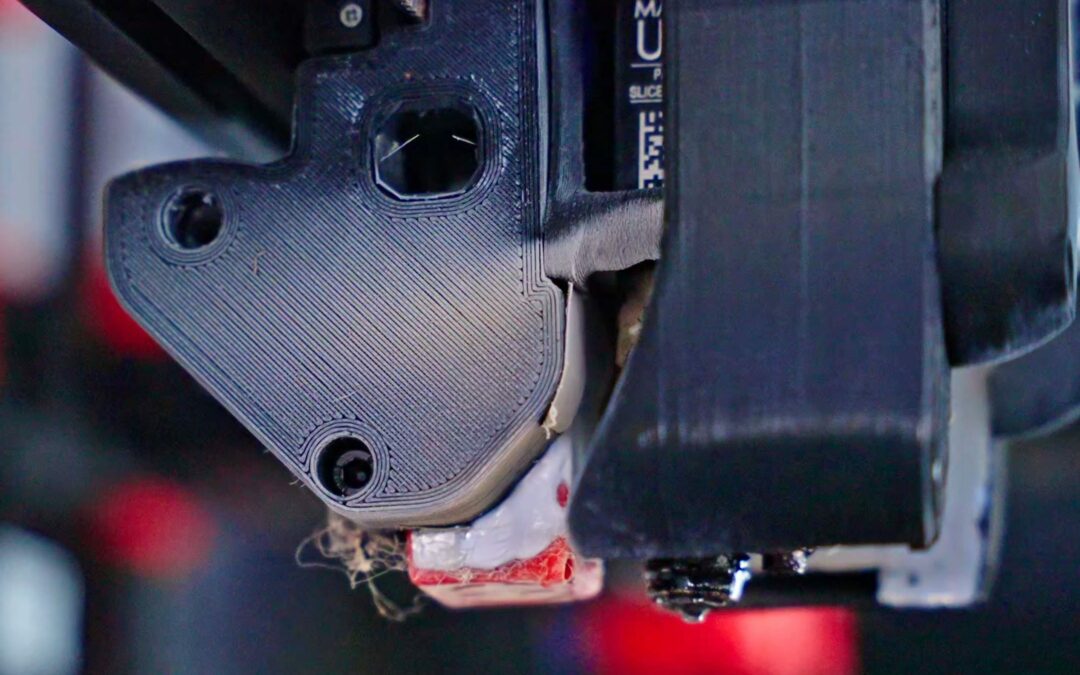

You might opt for PETG, thinking it’s safer because it doesn’t smell, but have you seen the white deposits accumulating on your printheads? That, too, is part of the equation. Even with relatively safe materials like PLA, you might detect a sweet cotton candy-like smell. I noticed a slight throat itch when spending an extended time in the same room as a running printer.

The Question

All this got me thinking: what are these 3D printers really releasing into the air, and what are the potential risks of inhaling these emissions? Is it possible to measure and compare the emissions from different filaments? Could they be dangerous, and what steps can you take to protect yourself from their potential health impacts? Let’s dig in and see what we can do to keep our lungs, bloodstreams, and brains safe from unintended exposure.

The Problem: Particulate Matter and VOCs

3D printer emissions can be categorized into two main types: particulate matter and VOCs. Understanding these is crucial for addressing any associated health risks.

Particulate Matter

Everyone’s familiar with N95 masks these days—they’re excellent against particles above 300 nanometers (nm), but not perfect at removing everything. For particles between 1 and 10 micrometers (µm), they rely on collision with filter material to get trapped. Ultra-fine particles, especially those smaller than 100 nm, behave more like gases. They’re affected by Brownian motion, making them tricky to capture.

Why is particle size such an important factor? The smaller the particles, the deeper they can penetrate into your body. Your respiratory system is efficient at capturing larger particles, but those under 2.5 µm can reach deep into your lungs. Particles even smaller than 100 nm may find their way into your brain, posing risks of inflammatory reactions or conditions such as Alzheimer’s.

VOCs: Volatile Organic Compounds

Think about solvents like acetone or formaldehyde. Many of these compounds come with a cocktail of acute and chronic toxic effects. Activated carbon filters are a common method to absorb VOCs, much like a sponge would do with water.

Understanding the Emissions

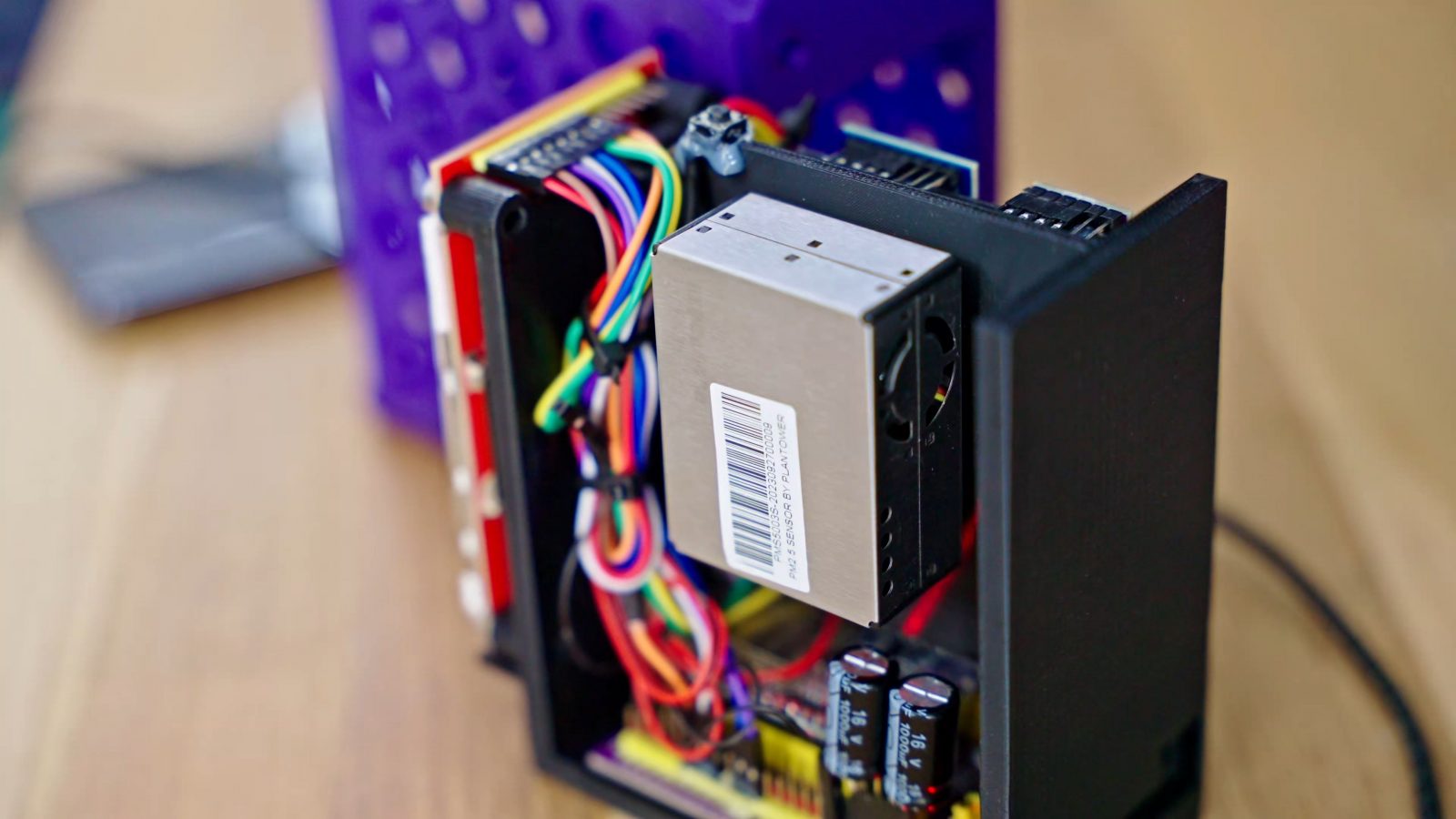

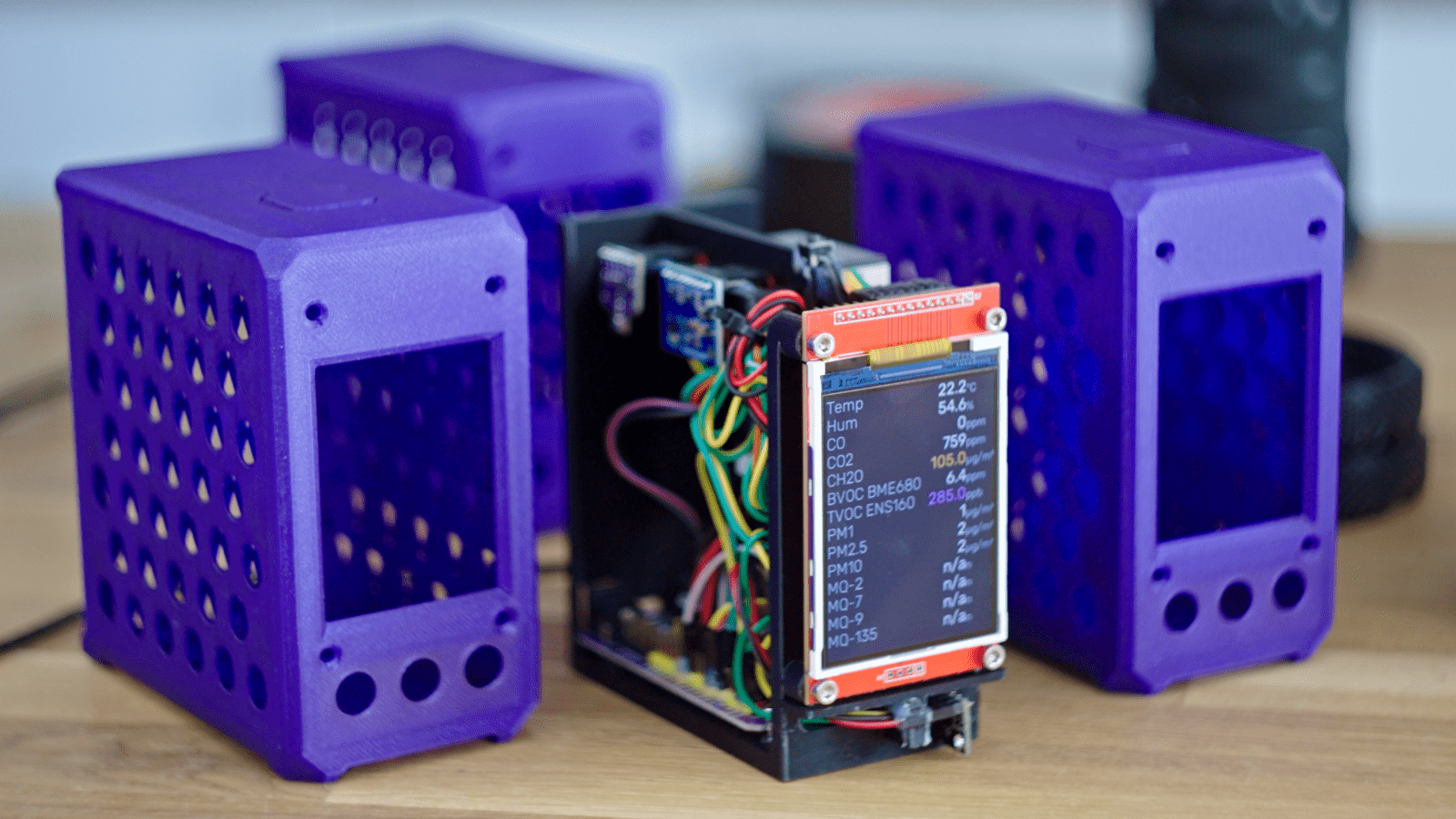

To genuinely get a grip on this issue, some testing and measuring are necessary. By employing sensor boxes and various filaments, you can identify what’s being emitted and gauge exposure risk.

Results with Different Filaments

- ABS: Often recognized by its distinct odor, ABS exhibits significant emissions. Yet, merely avoiding smelly materials doesn’t eliminate danger.

- ASA: While seemingly a better option with less noticeable odor, research has demonstrated it might emit more harmful particles than ABS.

- PETG and PLA: Present fewer odors but might still pose health concerns through unseen airborne deposits.

How to Protect Yourself

Your well-being shouldn’t take a backseat to 3D printing. Ensuring safe practices can help mitigate exposure:

-

Ventilation: Ensure good air circulation. This is the simplest yet effective step to dissipate harmful emissions.

-

Enclosures: By placing your printer in a dedicated enclosure, you can better manage and filter out harmful particles.

-

Filters: Install particle and VOC filters tailored to the specific threats posed by your printer’s emissions.

-

Regular Monitoring: Use air quality monitors to keep track of particulate matter and VOC levels around the printing area.

A Call to Action

Many people love 3D printing for its endless possibilities, but part of that enthusiasm must include responsibility. By understanding and acknowledging potential risks, you can take actionable steps to mitigate hazards.

It’s not just about letting creativity flow; it’s about doing so while ensuring you keep your environment, and by extension, your health, free from harm. Familiarize yourself with these insights and encourage others in the community to practice safer printing habits.

The Takeaway

As 3D printing continues to revolutionize the way personal and professional projects come to life, acknowledging and managing environmental health factors have become more critical than ever. Consider integrating these practices into your workflow to harness the full potential of 3D printing without unnecessary compromise to your well-being.

By staying informed and proactive, you’ll not only enhance your personal safety but also contribute to broader awareness within the community. Let’s keep creating—prudently and safely!